Packaged HVAC – RTU’s

The packaged HVAC unit is also called a RTU (roof top unit). This is a unit where the heating and air conditioning are both contained in the same assembly. These are called RTU’s because they are most often located on the roof, but can also be installed on the ground and ducted through a sidewall into a building. These units have also been found in residential properties, but mostly identified with commercial installations.

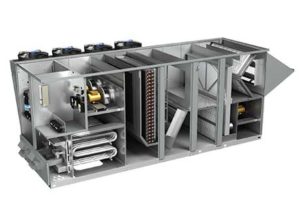

A Typical RTU consists of:

- An Evaporator Core

- A Condenser

- A Compressor

- A Blower motor and fan unit

- A Cooling motor and fan

- An Intake for Outside Air ( economizer )

- A Heat Source ( furnace )

- An Exhaust Flue

This unit is connected to the supply and return duct systems, located on the inside of the building.

Combining the heating and cooling into one unit saves on the footprint necessary to house both units, and also removes the need for two different locations for maintenance. This will also ensure that the heating and cooling will remain properly matched for size.

Advantages of an RTU:

- A RTU typically uses less energy; since it’s assembled and configured in a factory, under optimal conditions.

- The RTU is mounted on the roof, it does not take up any interior space.

- Installation is typically easier. The only interior components are the ducts needed to distribute the comforted air.

- Diagnostics and repair may be easier, as all of the components are in one location.

Disadvantages:

- Placement on the roof can require a crane

- Location on the roof can inhibit frequent maintenance

- Environmental damage can be frequent (hail or other weather damage)

Inspection

- Review the exterior of the unit for any visible damage or missing components, covers or other issues.

- Record the size and type for reporting purposes.

- Identify operating conditions – does the unit operate in one mode (heating or cooling)

- Has the interior filter been maintained

- Has the exterior metal fiber filter been maintained.

- Identify if there are any openings or other adverse conditions to exterior ductwork

- Review the electric connections and gas supply pipes.

- Locate a service or convenient electric outlet, in a general area of the unit.

The statistical life of an RTU unit is between 20 and 25 years. Units older than 25 years should be considered beyond statistical lifespan and budgeting for replacement should be made. Only damage to the fin systems, on the cooling side, should maintain the same reporting expectations as with residential split units. Exposed coils or excessively damaged fins will cause issues with the cooling.